Advantages of using graphite molds in the copper alloy casting process

Copper alloy casting is a common metal processing method, and graphite mold is one of the commonly used mold types in copper alloy casting. Our company specializes in the production of copper continuous casting molds.

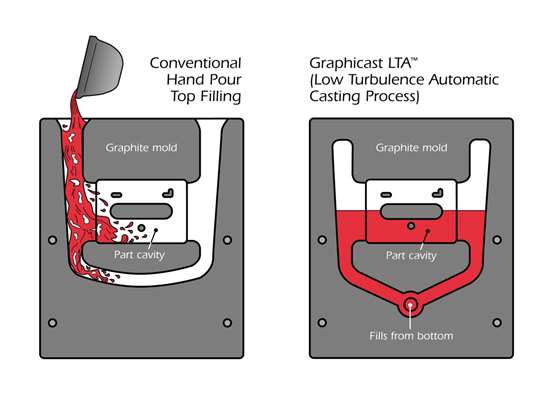

Graphite-Mold Casting Process Yields Cost Savings for Lens-Cutting

The Role of Graphite Molds in Continuous Casting

What is the application principle of graphite nozzle in casting process?

The Role of Graphite Molds in Continuous Casting

What's in the box: 1 PCS of graphite ingot molds, Convenient to Carry, Improve smelting efficiency. Specification: #1 Inner 90 x 18 x 22 mm, The

GanFindX 1 PCS (0.65KG Au-35ML) Pure Graphite Ingot Molds for Melting Casting Refining Gold Silver Metal Aluminum Copper Brass

How Graphite Molds Revolutionize the Copper Industry

范学村 on LinkedIn: Cost-effective custom graphite mold graphite bullet die

张小龙 on LinkedIn: High Pure Graphite Mold for Copper Brass Continuous Casting

张小龙 on LinkedIn: High Pure Graphite Mold for Copper Brass Continuous Casting