Use a DOE to Improve Consistency of Your Resin-Drying Process

Post-print UV curing method for improving the mechanical properties of prototypes derived from two-photon lithography

Epoxy Resin for Wood – Tutorial for Creative Ideas, DIY and Projects — BALTIC DAY

Application-specific unsaturated polyester resins, vinyl ester and gelcoats

Blow Molding Plastics Technology

VACUUM BAGGING PROCESS. Vacuum Bagging. Handling strength will develop in 10 hoursof room temperature curing and will fully cure within 24 to 36

Epoxy Resin Crystal Clear Food Safe Coating 4 Wood Horn Leather & 3D Prints

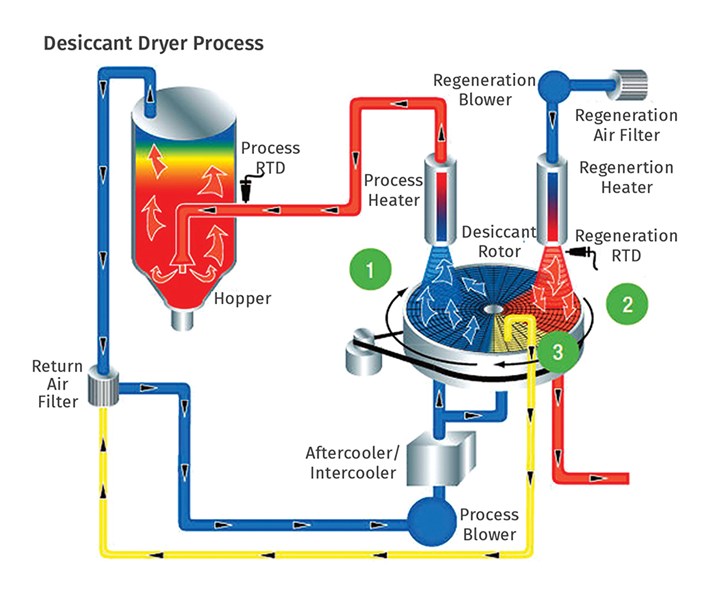

Maximizing Resin Drying Efficiency: The Impact of Time, Airflow, Temperature, and Dewpoint

bestpractices - Page 8 of 37

Wood drying - Wikipedia

Effects of Needle Coke Conductive Additive on the Performance of Graphite/ Resin Composite Plates - Wang - 2022 - ChemistrySelect - Wiley Online Library

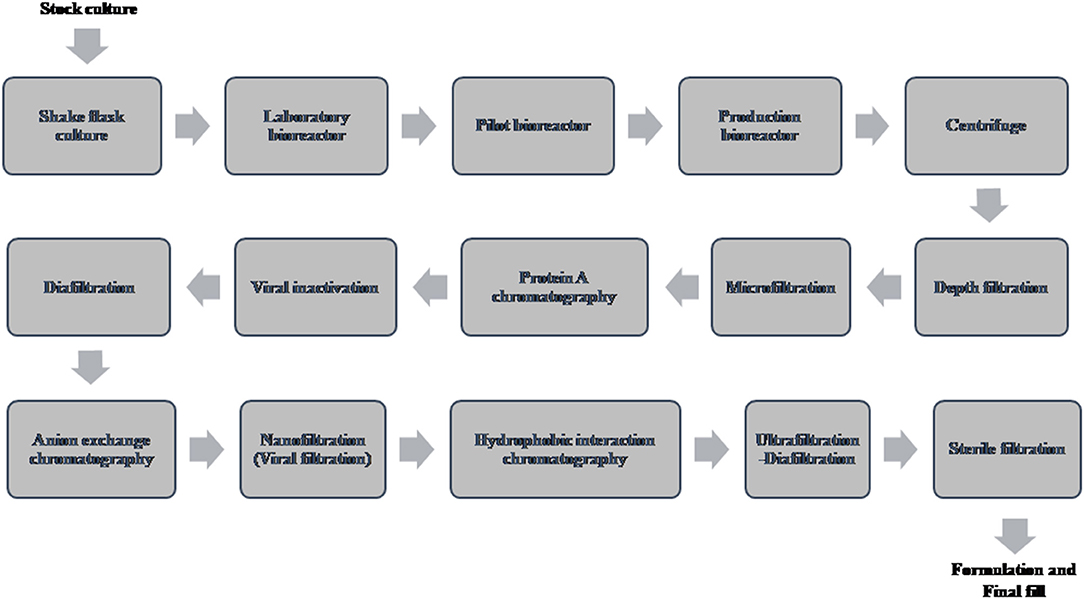

Frontiers Recent Developments in Bioprocessing of Recombinant Proteins: Expression Hosts and Process Development

Design of Experiments (DoE) and Process Optimization. A Review of Recent Publications

Maximizing Resin Drying Efficiency: The Impact of Time, Airflow, Temperature, and Dewpoint

4 Simple Ways to Dry Resin Art - wikiHow