Laser Blanking - AHSS Guidelines

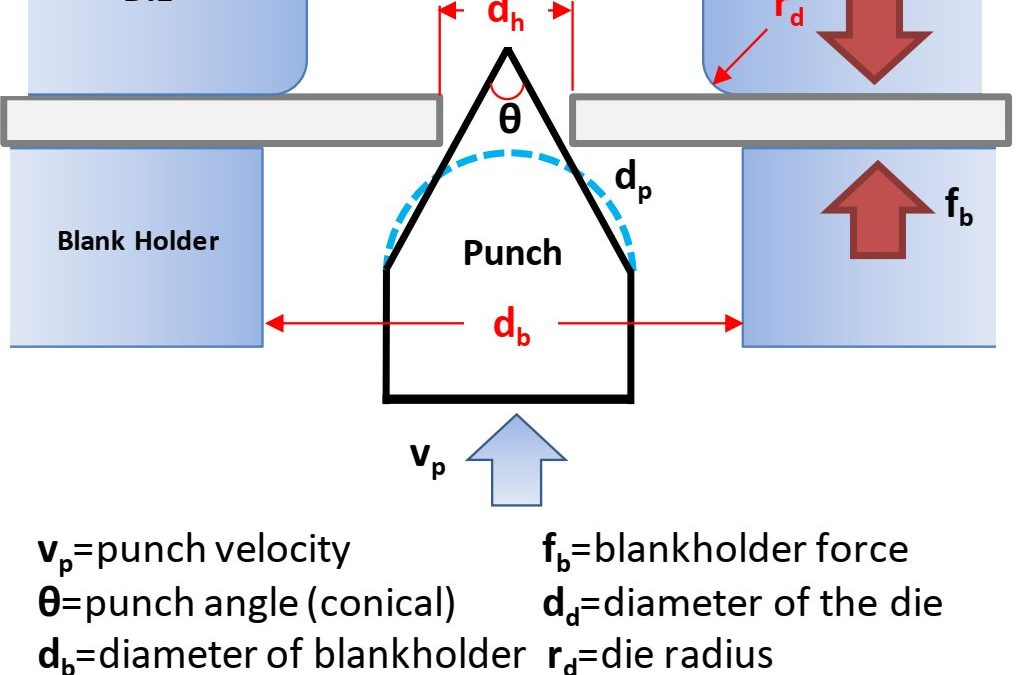

Conventional blanking requires high press forces to shear the sheet metal. As steel strength increases, snap-through tonnage also increases, potentially leading to press and tooling damage. Over time, clearances may change, affecting edge quality.

Laser Welded Blanks Archives - AHSS Guidelines

Cutting Archives - AHSS Guidelines

Introduction - AHSS Guidelines

Shear Affected Zone - AHSS Guidelines

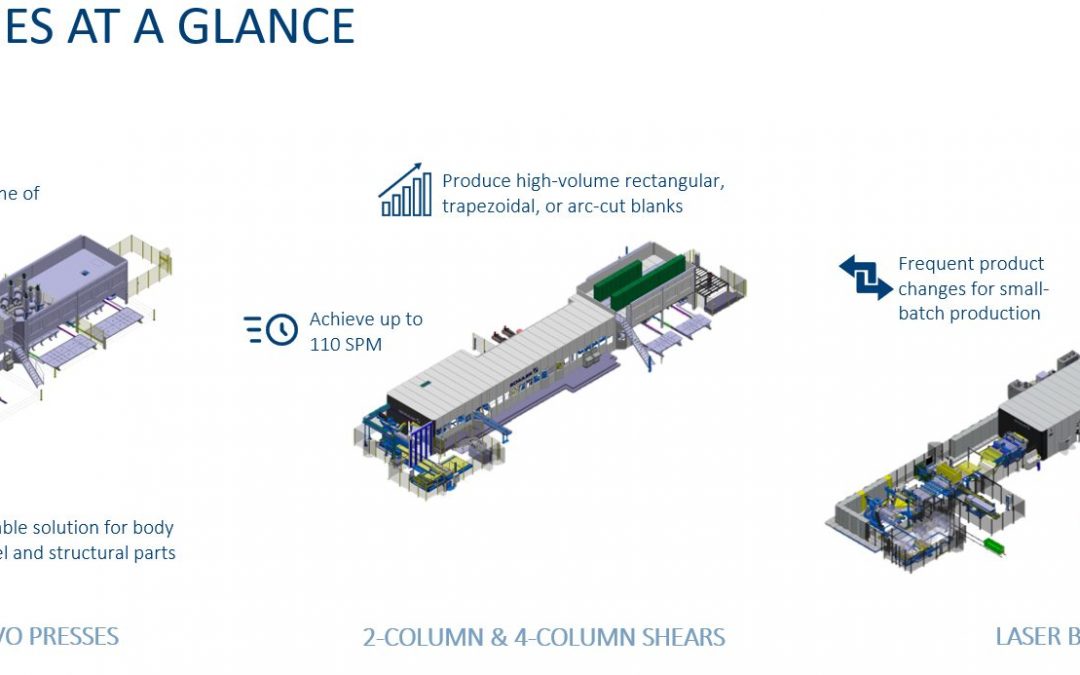

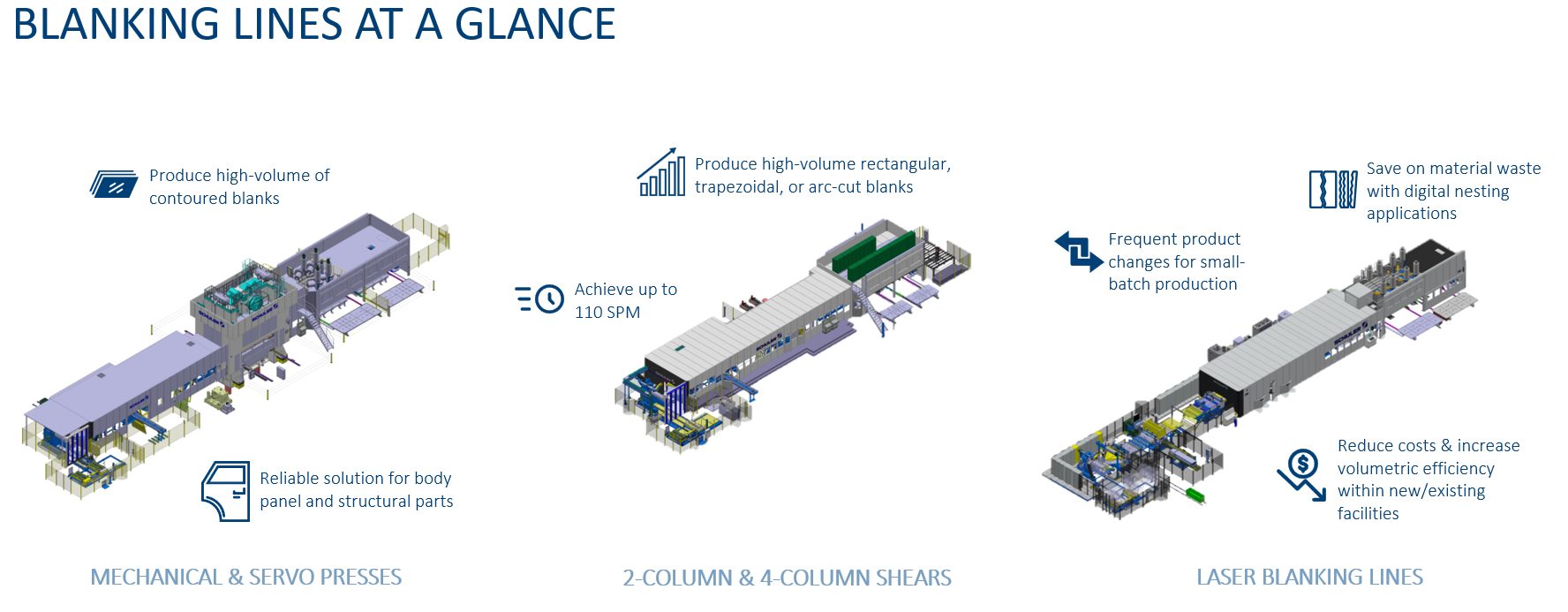

LaserCoil Technologies LLC

SAZ Archives - AHSS Guidelines

R&D Update: Blanking and edge fracture in flanging of AHSS, Part II

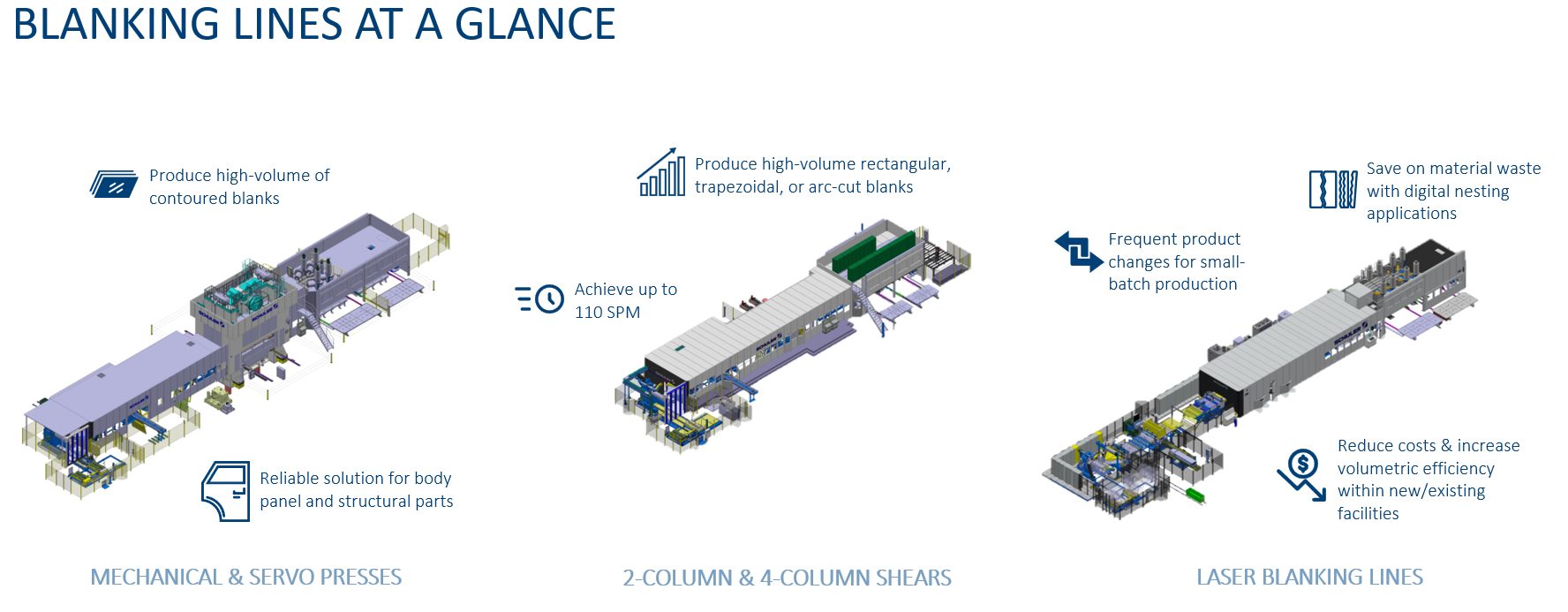

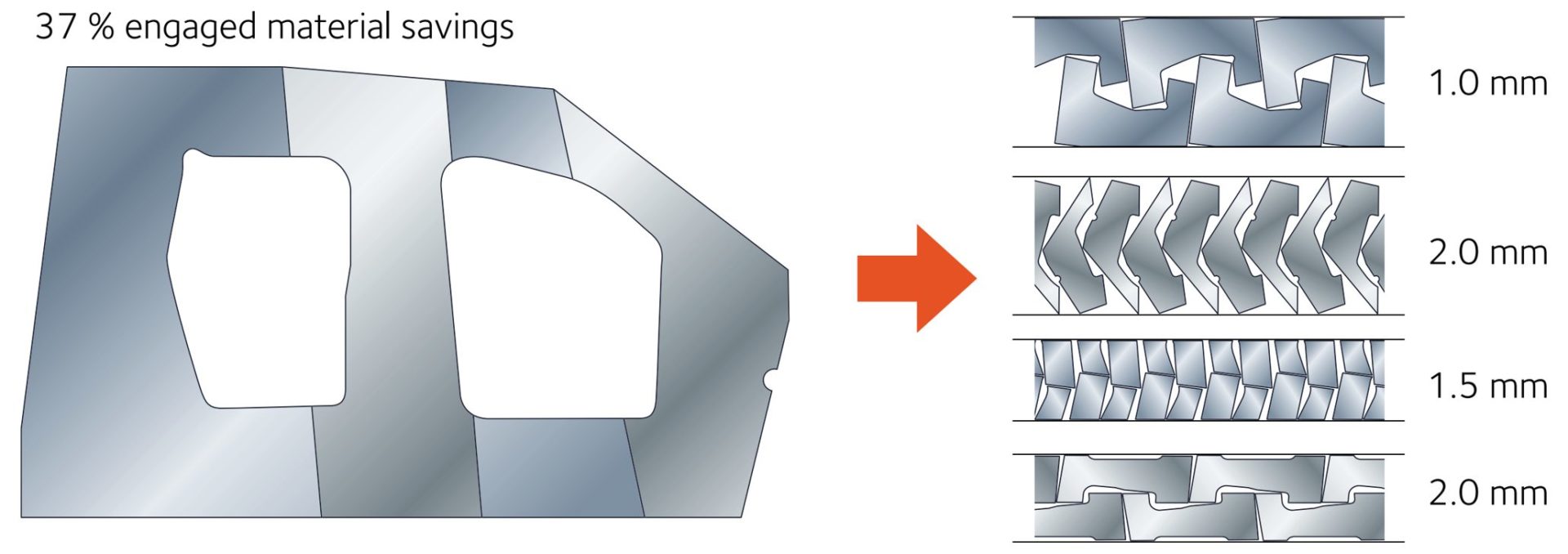

Advantages of laser welded blanks

Joining Archives - Page 3 of 12 - AHSS Guidelines

Generation mechanism of residual stress at press-blanked and laser

Blanking Archives - AHSS Guidelines

Shear Affected Zone - AHSS Guidelines

R&D Update: Determining sheared-edge formability of AHSS

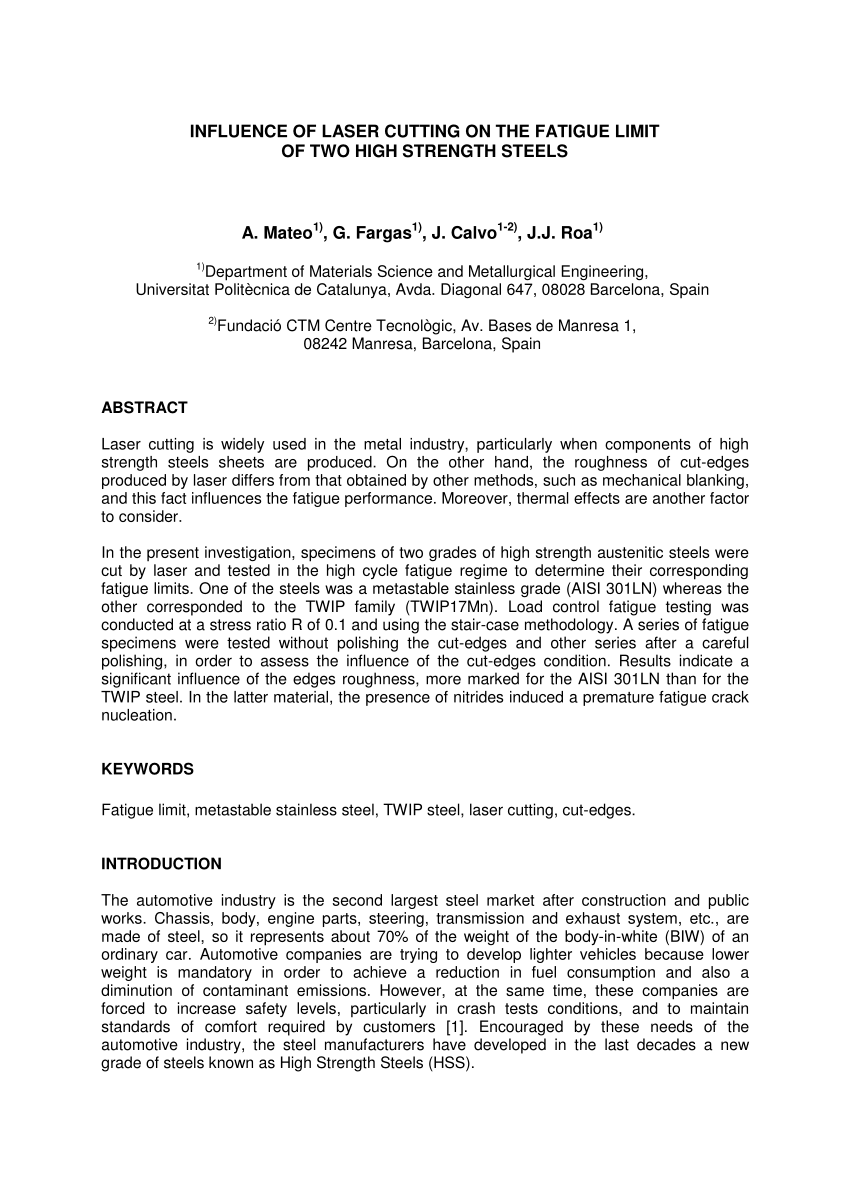

PDF) Influence of laser cutting on the fatigue limit of two high

Laser Blanking - AHSS Guidelines