Die Science: Piercing, cutting aluminum without slivers

Slivers are the result of the aluminum interfacing with the cutting sections or punches. To reduce the production of slivers the severity of friction at the point where the two surfaces interface must be reduced. The general rule for cutting materials is the softer the metal the smaller the cutting clearance.

Die Science - Splitting in A Stretch Flange - The Fabricator

Custom Piercing Tools

Investigation of a Modified Fine Piercing Process on Extra Deep

Die Science: Piercing, cutting aluminum without slivers

FE Simulations of Piercing and Trimming of AL and AHSS Alloys

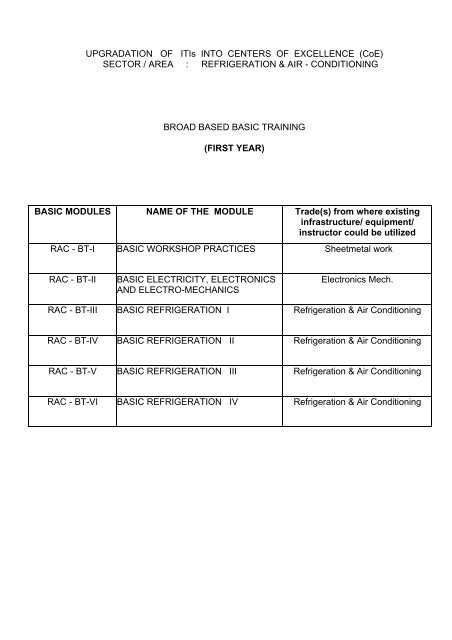

UPGRADATION OF ITIs INTO CENTERS OF EXCELLENCE (CoE)

Nano-hardness distribution as a function of the distance from the

Die Science: Losing the art of die making and metal stamping

A Review of Fine Blanking: Influence of Die Design and Process

Bertrand Piccard's Laps Around the World

Art Hedrick: Contributing Writer at Dieology LLC - Page 3

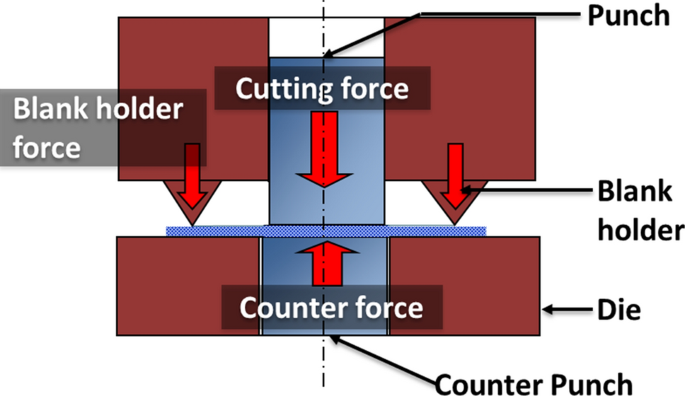

Shearing process: blanking and piercing [1]

Residual stress in sheared edge for quenched steel sheet. Residual

Art Hedrick: Contributing Writer at Dieology LLC - Page 3

Die Science: Piercing, cutting aluminum without slivers