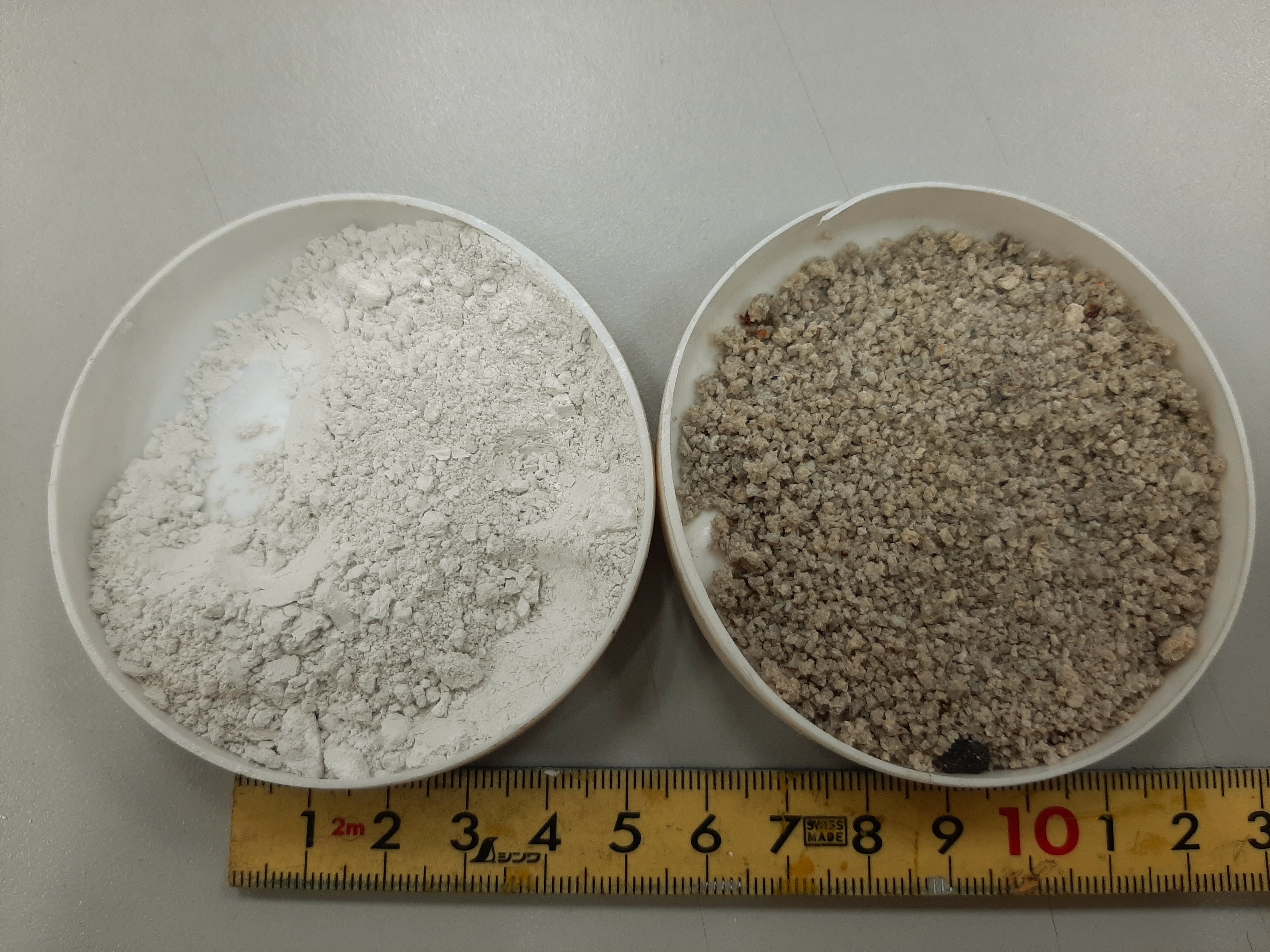

Optimized Processing to Reduce Crystalline Silica in Ground

Over the past several years, there has been a murmur in the coatings industry with regards to the concentration and levels of crystalline silica within various paint formulations, particularly architectural coatings. While there are countless architectural coating formulations, commonly the largest component on a volume basis is calcium carbonate. The combination of the regulatory focus on crystalline silica, in conjunction with the impact calcium carbonate can have on a formulation’s crystalline silica levels, inspired Imerys to both re-evaluate and optimize the processing of calcium carbonate . . .

The combination of the regulatory focus on crystalline silica, in conjunction with the impact calcium carbonate can have on a formulation's crystalline silica levels, inspired Imerys to both re-evaluate and optimize the processing of calcium carbonate to support paint formulators to continue to drive down the crystalline silica levels in their products.

Silica

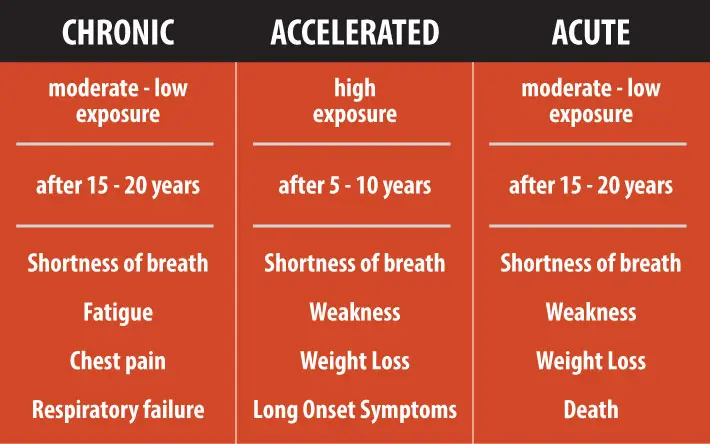

Silicosis Prevention: Silica in the Repair Environment

Quality by design (QbD) in the formulation and optimization of

Ground granulated blast-furnace slag - Wikipedia

Engineering Controls for Respirable Crystalline Silica Hazards

Steps to Reduce Nuisance Dust & Prevent Silica Exposure - Gilson Co.

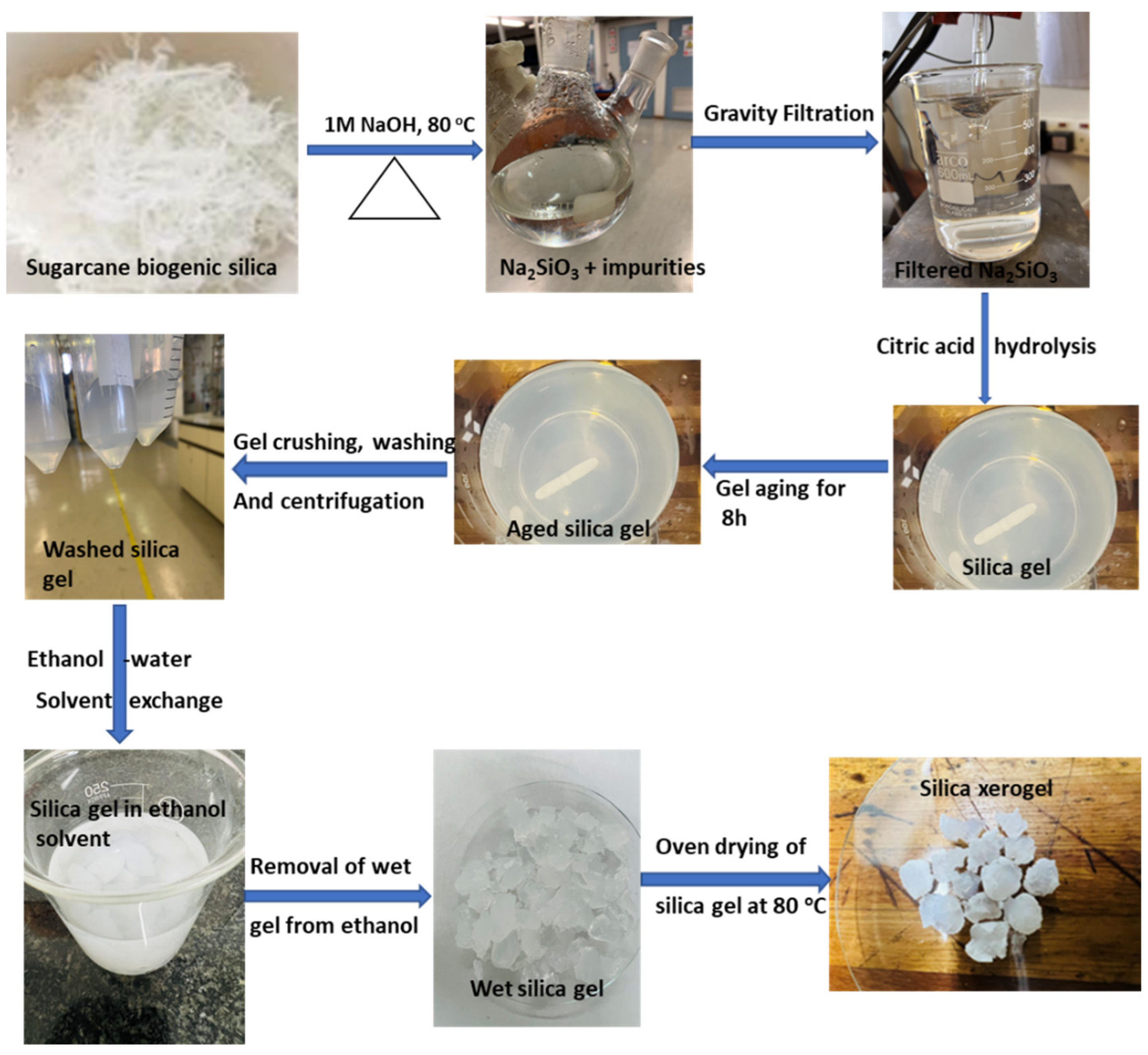

Nanomaterials, Free Full-Text

Highly Pure Silica Nanoparticles with High Adsorption Capacity

Silicosis Prevention: Silica in the Repair Environment

Removing Silica from Industrial Water

Ground Calcium Carbonate Versus Feldspathic Minerals, 2012-04-02

Easy Work Practice Solutions That Reduce Respirable Crystalline

Sustainability, Free Full-Text

Reduce Exposure to Silica Dust Concrete Construction Magazine

Silicosis Prevention: Silica in the Repair Environment

:max_bytes(150000):strip_icc()/15195145290_72c555d4d8_k-58c1a8f93df78c353c47634c.jpg)