G109 Thermal Conductive Glue - Silicone - Strong Adhesion - Temperature Range

G109 Thermal Conductive Glue. Plus, with its wide service temperature range and high thermal conductivity, it can be used in various industries and

10gram Thermal Conductive Glue, Silicone Glue

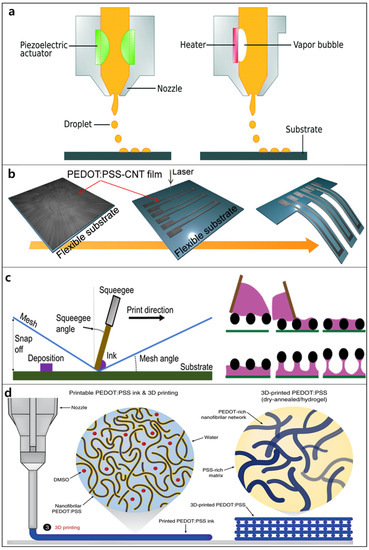

Polymers, Free Full-Text

Thermal Compounds & Supplies, Fans, Heat Sinks & Cooling, Computer

10gram Thermal Conductive Glue, Silicone Glue

GLUE 101: Glue Operational Temperature

It has heat conducting properties, strong adhesion. Helps disperse the heat from Chipset to heatsink effectively.

GENNEL G109 75grams Thermal Glue, Thermal Conductive Plaster, Silicone Viscous Adhesive Compound for LED GPU Chipset Printer MOSFET Heatsink Cooling

10gram Thermal Conductive Glue, Silicone Glue

High Thermal Conductivity - With a thermal conductivity rate of 0.975W/m-K, this thermal conductive glue helps disperse heat effectively from MOSFETs, LEDs, ICs, GPU chipsets, and other electronic components that require direct bonding. It is suitable for all heatsinks without a fixed clip, and can be used for a wide range of applications.

Bymugo 2 Pack 10g (20g in Total) HY910 0.975W/m-k Thermal Conductive Glue, High-Performance Thermal Plaster, Silicone Viscous Adhesive Cooling

ZS-GF-Z10 Thermally Conductive Silicone Grease/Paste

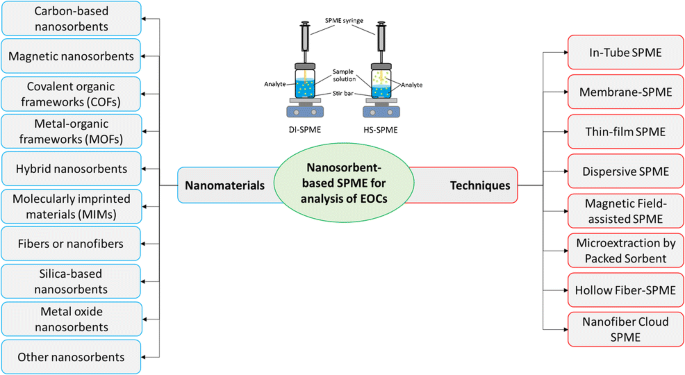

Nanosorbent-based solid phase microextraction techniques for the monitoring of emerging organic contaminants in water and wastewater samples

Non-Electrical Conductive,Non-corrosive ,Non-toxic,Suitable for all heatsink without fixed clip. It has heat conducting properties, strong adhesion.

GENNEL G109 10gram Thermal Conductive Glue, Silicone Glue, Thermal Plaster, Silicone Viscous Adhesive Compound, Heatsink Glue for LED GPU MOSFET

Chapter 3 - Findings and Applications, Bridges for Service Life Beyond 100 Years: Innovative Systems, Subsystems, and Components

Full article: Synthesis and Modifications of Epoxy Resins and Their Composites: A Review