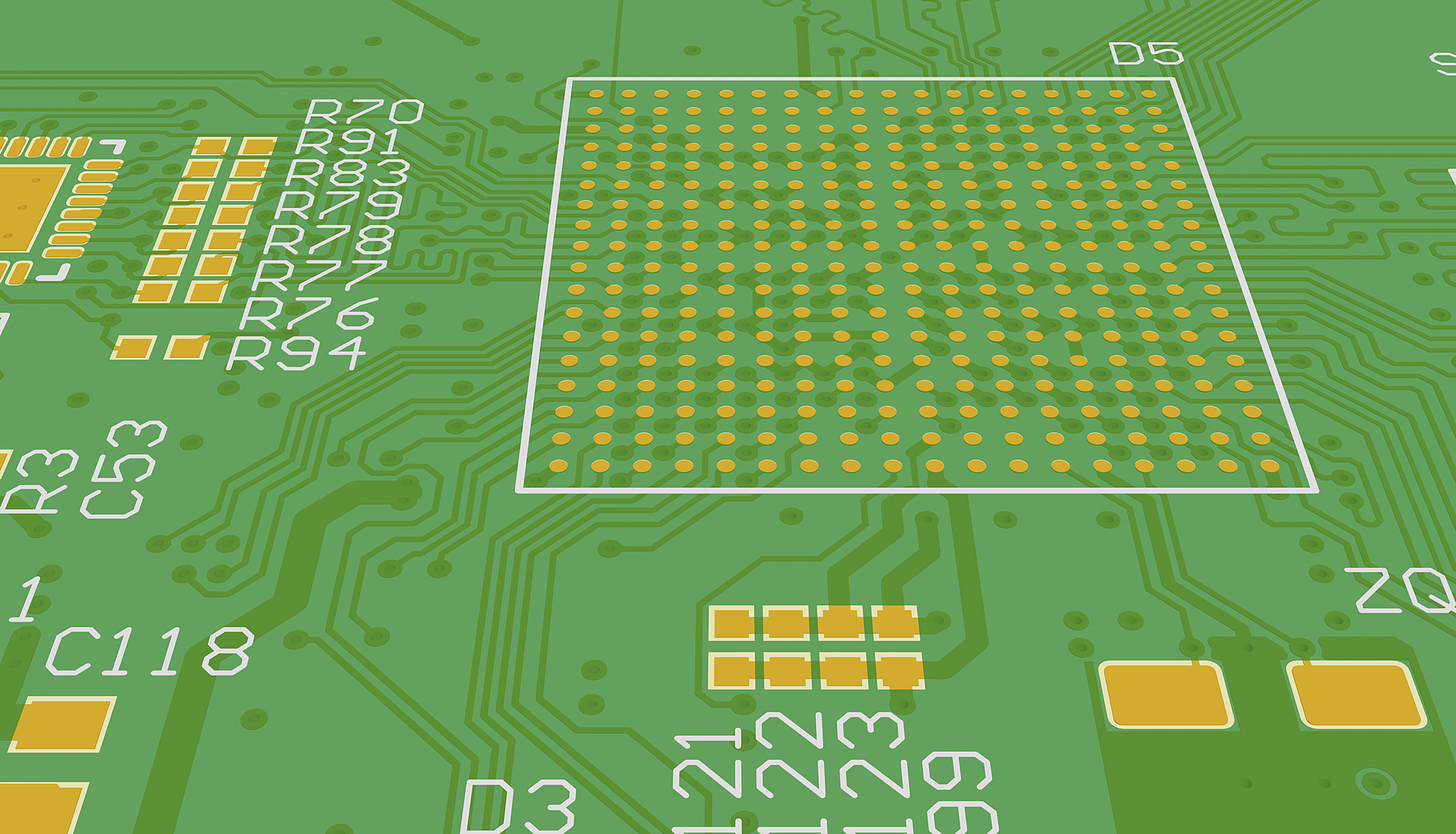

Understanding Silk Screen Technology in Printed Circuit Board (PCB)

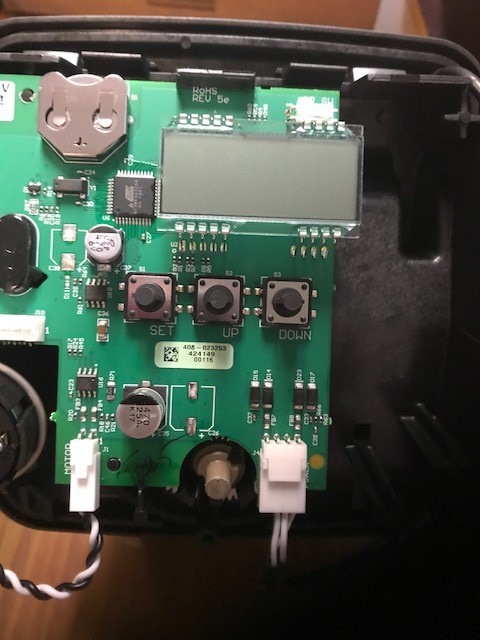

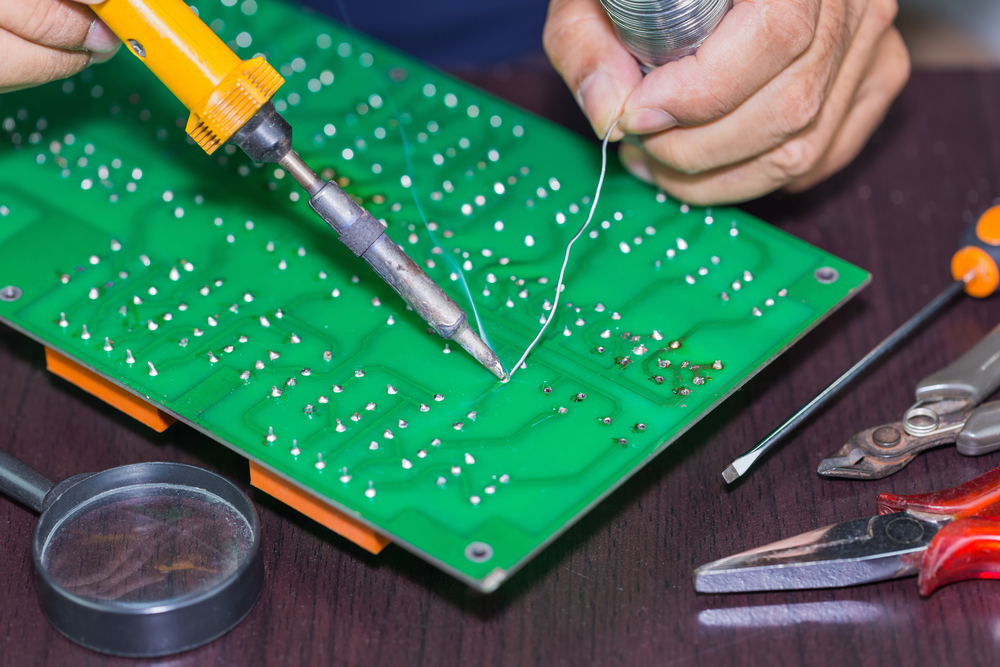

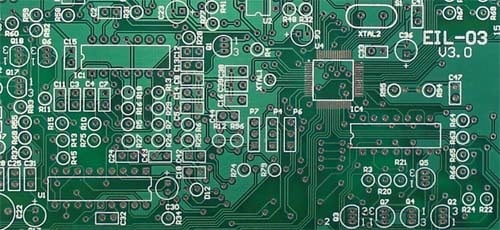

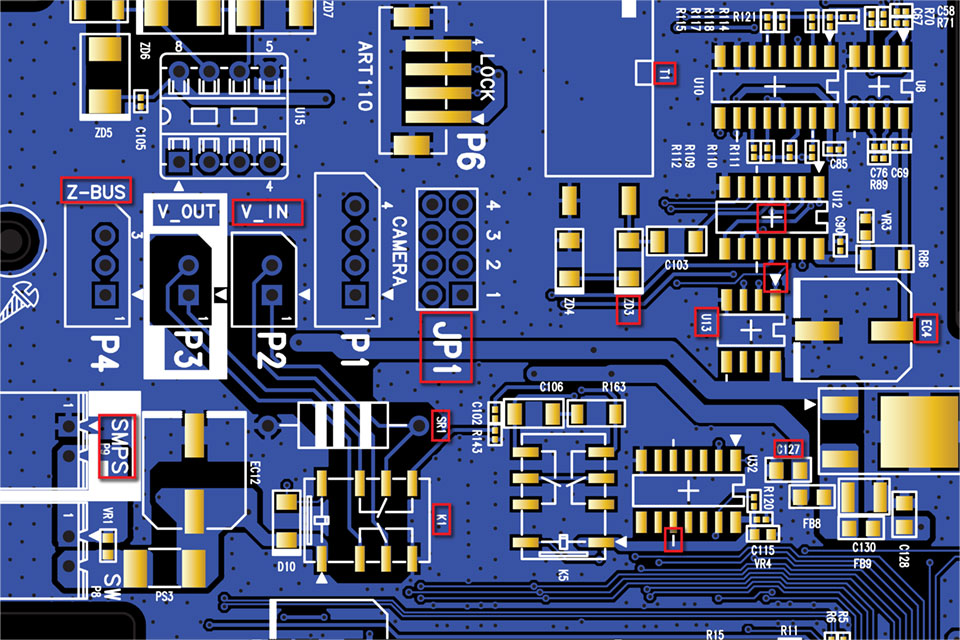

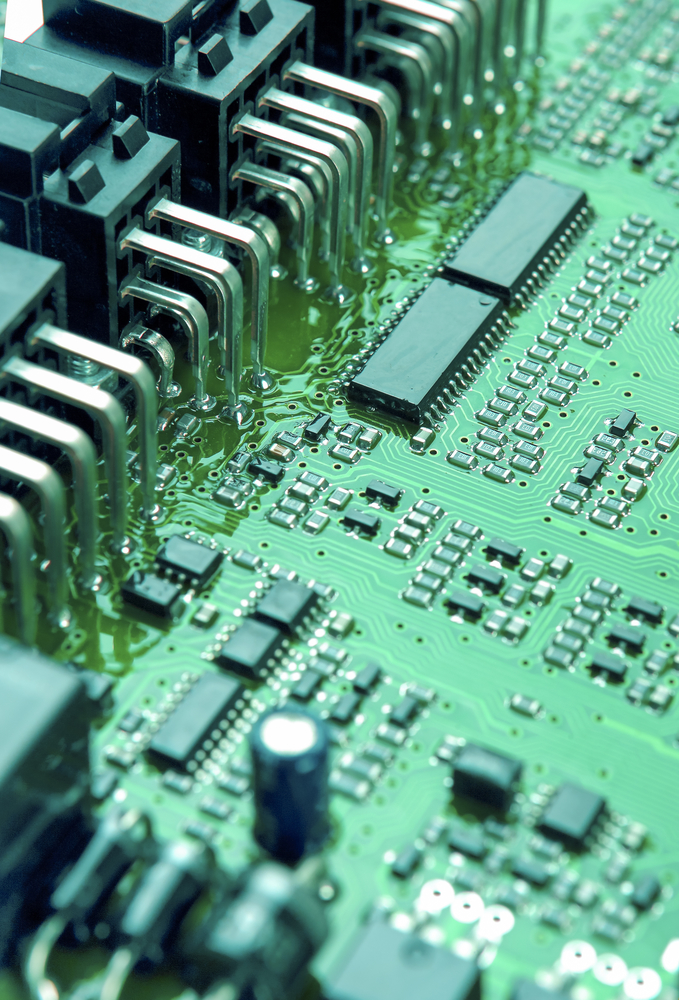

Adding the silkscreen layer onto a printed circuit board is the final step in the fabrication process. Silkscreen is a layer that uses ink traces to identify all the PCB board components, test points, parts of the PCB, warning symbols, logos and marks etc. These shapes, numbers, and letters really aren’t some new language. They can also communicate the function of each of the pins. This silkscreen is applied on the component side; all though you may find the use of silkscreen on the solder side is also not uncommon, which will increase the cost. Essentially a detailed PCB silkscreen will benefit both the manufacturer and the engineer to locate and identify all the components.

How To Get Satisfied PCB Silkscreen - A Step-by-Step Guide

What is PCB (printed circuit board) and how it's made - Soldered

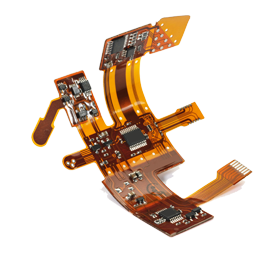

Applications of Flexible Circuits, Flex Circuits

Is Surface Mounted Technology Better Than Through-Hole Technology?

PCB Assembly Services, EMS Provider, Cable Wire Cutting

What is a printed circuit board -- Basic PCB Concepts?

Yun Industrial Acme PCB Assembly

Silkscreen Sierra Circuits

The Three Historical Figures Who Made Printed Circuit Boards a Possibility