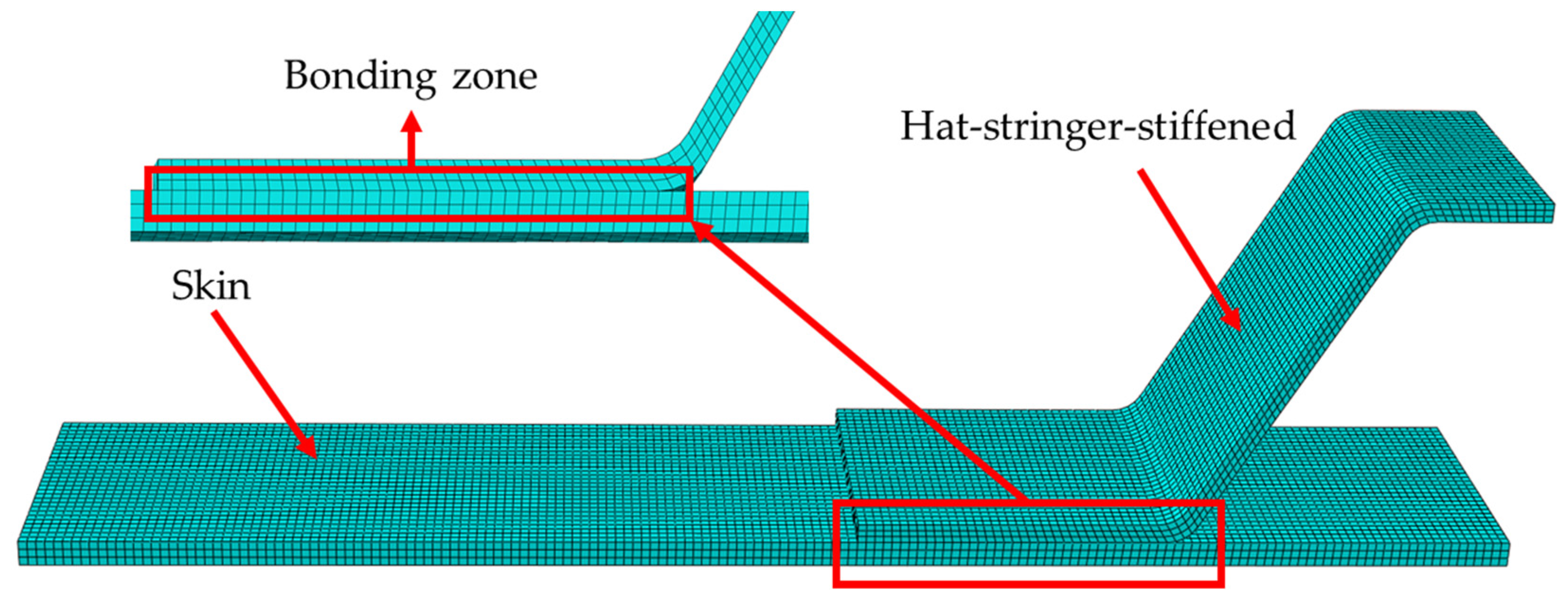

Typical top-hat-stiffener configuration

Design Optimization and Higher Order FEA of Hat-Stiffened Aerospace Composite Structures

Raju RAJU, Research Academic, PhD - Composite Structures, UNSW Sydney, Kensington, UNSW, School of Mechanical and Manufacturing Engineering

Delamination failure of composite top-hat stiffeners using finite element analysis - Raju, B Gangadhara Prusty, Don W Kelly, 2013

Waveform analysis of VIP THS, Layup 4 specimens-FBG-AE sensor

Materials, Free Full-Text

Delamination failure of composite top-hat stiffeners using finite element analysis - Raju, B Gangadhara Prusty, Don W Kelly, 2013

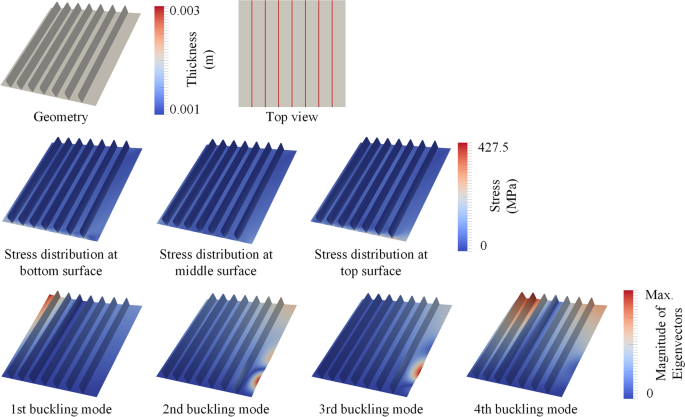

Design of stiffened panels for stress and buckling via topology optimization

Dynamic behavior of top-hat bonded stiffened composite panels: Experimental characterization - ScienceDirect

Measured Strain & load and Strain rate & load against time for Outer

Typical top-hat-stiffener configuration

Top hat stiffeners: A study on keel failures - ScienceDirect

VARTM top-hat-stiffener laminate configuration

Damage mechanics of top-hat stiffeners used in FRP ship construction - ScienceDirect

Bickmore Kahl Hat Stiffener - Great for Fabric & Felt Hat Brims - Will Not Affect Tone, Texture, or Color