In-cycle spline milling saves production costs

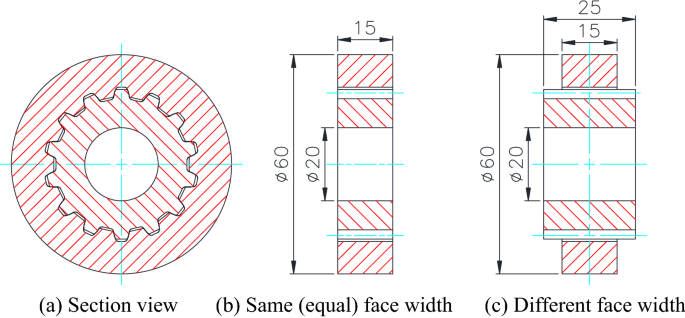

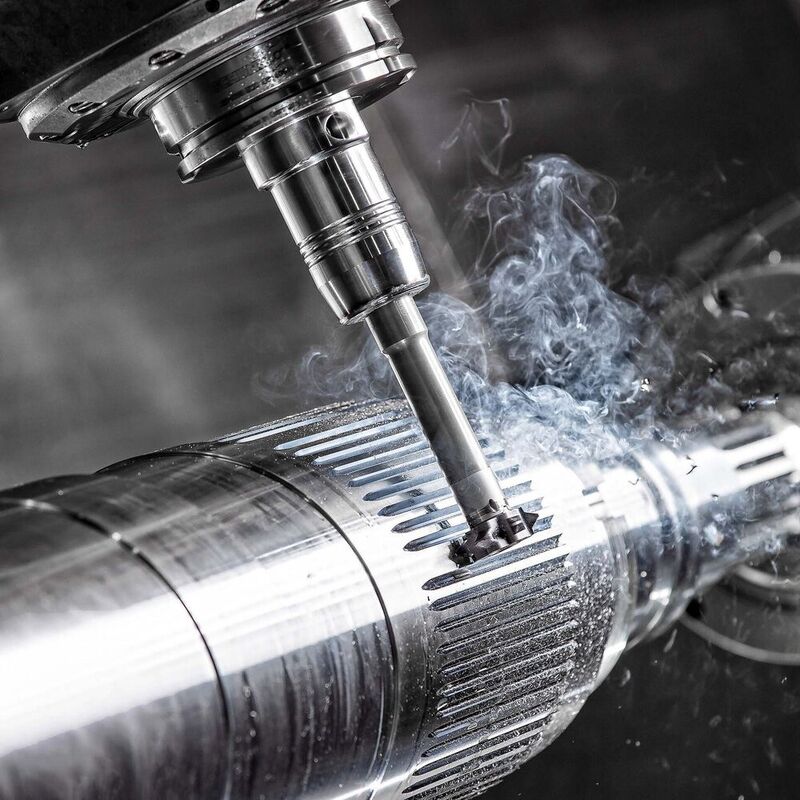

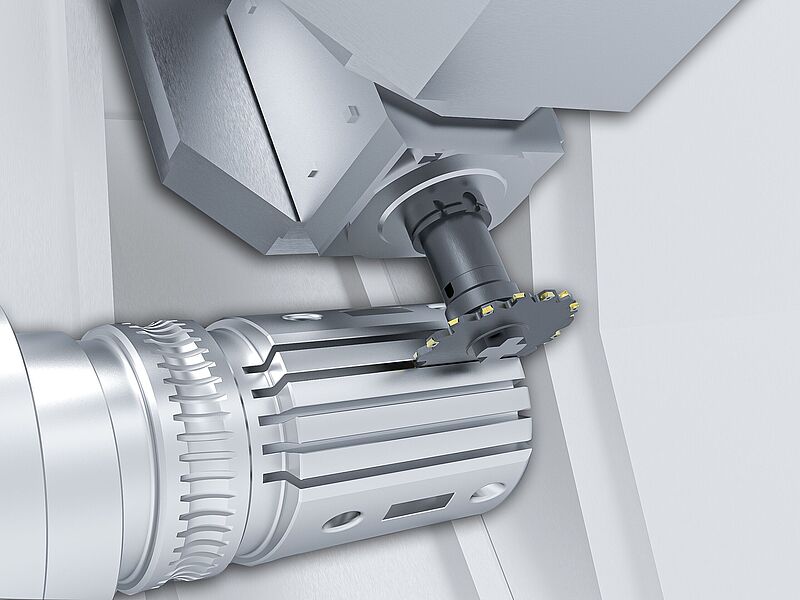

(Bild: Horn/ Sauermann) Tooling manufacturer Horn highlights one of its customers that is saving costs by not only turning a drive shaft on a multi-tasking CNC lathe but also milling a spline in the same set-up, an operation that was previously subcontracted out.

Actofive Machines Signature X Gearbox Crankset to Spice Up Your Gearbox Bike - Factory Tease - Bikerumor

Bridgeport Milling Machine Part Gear Spline Shaft Gear Shift Pinion Shaft Fit 1p

Pratt Whitney Spline Mill. Still hooked up to power and operational. Buyer welcome to come out and see machine before purchase. Seller will load

Pratt Whitney Spline Mill (1 of 2) Milling Machine (still under power)

Milling - WFL

Manufacturing Machinery World December 2022

BROACHING WITH INTERNAL COOLING – MTDCNC

Custom CNC Machining Machined Aluminum 7075 Profile Racing Spline Drive Sprocket for Bike Part - China Aluminum Sprocket, CNC Machined Sprocket

Machining an Internal Spline

How to Keep Costs Down with Low Volume Production Machining - Schantz Machine & Fabrication

Spline Cutting Machine, Spline Hobbing Machine

SAVE - Enco

Horn have all the Gears to help you skive off – MTDCNC

Manufacturing Machinery World December 2022

Speeding Up Splines Modern Machine Shop

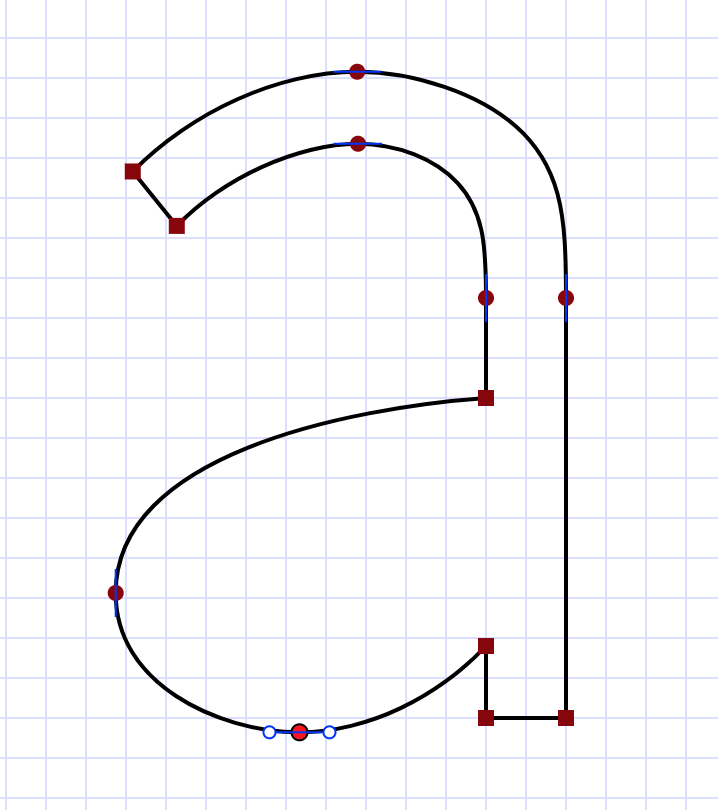

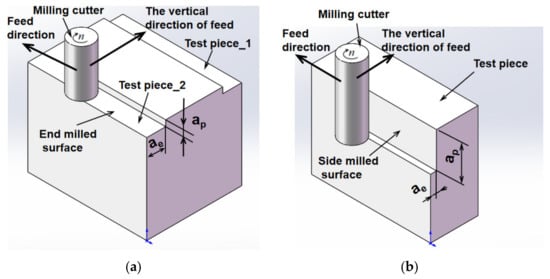

Applied Sciences, Free Full-Text