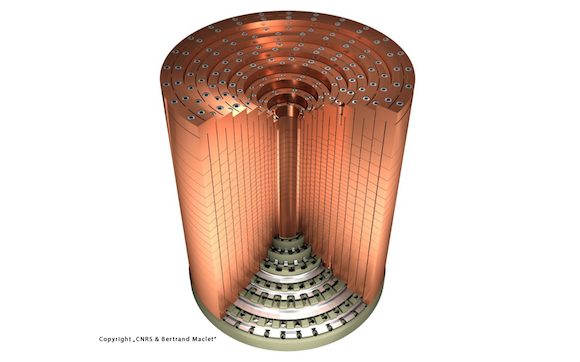

Photo images for two samples of: (a) copper powder, and (b) alumina

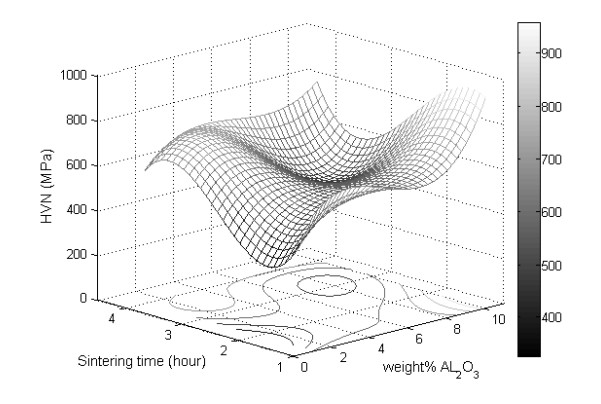

Download scientific diagram | Photo images for two samples of: (a) copper powder, and (b) alumina powder (both at X5 optical magnification). from publication: DOE-based experimental investigation and optimization of hardness and corrosion rate for Cu-x%Al 2 O 3 as processed by powder metallurgy | Copper alumina (Cu-x%Al 2 O 3) was prepared from micro-sized powder particles through the powder metallurgy (PM) process. Experimental runs were designed according to the design of experiments (DOE) methodology to investigate the effect of alumina concentration and sintering | Powder Metallurgy, Alumina and Hardness | ResearchGate, the professional network for scientists.

Characterization of electrochemical deposition of copper and copper(I) oxide on the carbon nanotubes coated stainless steel substrates

DOE-based experimental investigation and optimization of hardness and corrosion rate for Cu-x%[Al.sub.2][O.sub.3] as processed by powder metallurgy. - Document - Gale Academic OneFile

Strained few-layer MoS2 with atomic copper and selectively exposed in-plane sulfur vacancies for CO2 hydrogenation to methanol

Class 10 Chemistry Worksheet on Chapter 1 Chemical Reactions and Equations - Set 1

Powder Metallurgy: What Is It? Processes, Parts, Metals Used

DOE-based experimental investigation and optimization of hardness

TEM images of alumina (a) and copper oxide (b) nanoparticles.

Structural, mechanical and thermal characteristics of Al-Cu-Li particle reinforced Al-matrix composites synthesized by microwave sintering and hot extrusion - ScienceDirect

Omar BATAINEH, Associate Professor, PhD, Jordan University of Science and Technology, Irbid, Just, Department of Industrial Engineering

Encapsulated Copper-Based Phase-Change Materials for High-Temperature Heat Storage

DOE-based experimental investigation and optimization of hardness and corrosion rate for Cu-x%[Al.sub.2][O.sub.3] as processed by powder metallurgy. - Document - Gale Academic OneFile